Gyratory Crusher Construction - Kaseo Heavy …

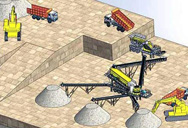

Gyratory Crusher Mining Fundamentals. Gyratory crushers are known for their high production rates with a higher capacity than a jaw crusher In order to get cubical material out of a gyratory crusher it should be choke fed Gyratory crushers are not suitable for crushing clay as clay will clog the crusher Construction and Working of Gyratory Crushers

Construction Of Gyratory And Jaw Crushers

Gyratory Crusher Mining Fundamentals. Gyratory crushers are not suitable for crushing clay, as clay will clog the crusher. Construction and Working of Gyratory Crushers Gyratory crushers consist of a shell, which is sloping inwards, and a long spindle that is suspended from a bar at the top with the help of pivots.

Gyratory Crusher - an overview | ScienceDirect …

Gyratory Crusher Construction. The outer shell of the crusher is constructed from heavy steel casting or welded steel plate, with at least one constructional joint, the bottom part taking the drive shaft for the head, the top, and lower shells providing the crushing chamber. If the spindle is carried on a suspended bearing, as in most primary gyratories, then the spider carrying the …

Gyratory Crusher Construction - ostseepension …

Gyratory Crusher Construction. Construction of gyratory crushers the important symbol of modern road transportation, the highway is the key project of the national transport network constructionighway construction brings the development of gyratory crusher industry, and then lead to the demand increase of crusher and mill.

Gyratory Crusher Construction Equipment

Gyratory Crusher Construction Equipment. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

How does a Gyratory Crusher Works - Mineral …

19.05.2013 · In this video we will see what are the basic features of a Gyratory Crushers. Gyratory Crusher are used in Mineral Processing Industry for size reduction of Run off Mine (ROM) materials to size ...

Gyratory crushers - DAVON – Mining and …

Gyratory crushers; Mobile crushers; Grizzly; Accessories; Grabs. Clamshell grabs HCD, HCDK, HCU; Orange Peel Grabs HPD ; Timber grabs HDK, HDS; MCD motorised clamshell grab; Motor Orange Peel Grab MPD; Motor Timber Grabs MDD; Accessories; Buckets. Loading buckets; Digging buckets; Special construction machinery. Cleaning attachment; STATIONARY CRUSHER …

Gyratory Crusher Animation - YouTube

01.08.2016 · The basic principle of how does a gyratory crusher work using an animation. https://www.911metallurgist.com/equipment/crushing/

Gyratory CRUSHERS - CITIC Heavy Industries Co Ltd

CITIC-HIC PXZ Gyratory Crushers Series II CITIC-HIC PXZ Series II Primary Gyratory Crushers offer a range of crusher sizes to suit the most demanding of applications in some of the world’s largest mining projects. With feed sizes up to 1200mm and capacities of 8000TPH. Combined with high speed (600rpm) and a range of eccentric

Gyratory Crushers - Mineral Processing & …

Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501).

Crusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) …

60-110E SUPERIOR® Primary Gyratory Crusher …

Key features of the SUPERIOR® 60-110E primary gyratory crusher. Features. liming’s SUPERIOR 60-110E primary gyratory crusher provides a redesigned Spider, a one-piece bottom shell and a new rim liner retention system. These improvements and redesigned components are also interchangeable with existing 60-110 MK-ll crushers.

Gyratory Crusher - Mining Fundamentals

Gyratory crushers are known for their high production rates, with a higher capacity than a jaw crusher. In order to get cubical material out of a gyratory crusher, it should be choke fed. Gyratory crushers are not suitable for crushing clay, as clay will clog the crusher. Construction and Working of Gyratory Crushers

Construction Of Jaw And Gyratory Crusher

Gyratory crushers can accept 810 moisture in operation, but the fine content should be preferably less than 10. The crushing action in gyratory crushers is regarded as rings or helics spirals of feed down through the crusher of which a single section may be regarded as similar to the jaw crusher.

Crushers - All crusher types for your reduction …

Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the stone size of the processed material is small enough by nature and the traditional primary crushing stage is not needed. In these cases, also cone crushers can carry …

What Is The Construction Of Gyratory Crusher

Disgin And Construction Of Laboratory Gyratory Cone Crusher. gyratory crusher foundation design XSM is a leading global manufacturer of crushing and milling equipment gyratory crusher foundation designXSM also supply individual gyratory crusher foundation design crushers and mills as well as spare parts of them disgin and construction of laboratory gyratory cone crusher …

Cone / Gyratory Crusher Crushers | Engineering360

60-110E SUPERIOR® Primary Gyratory Crusher from liming. Key features of the SUPERIOR ® 60-110E primary gyratory crusher. Features. liming ’s SUPERIOR 60-110E primary gyra tory crusher provides a redesigned Spider, a one-piece bottom shell and …