Two And Three Roll Mills Procedure - Apollo Grill & Pizzeria

Two And Three Roll Mills Procedure. Mixing mills also rolling mills are used for the manufacture of stone compounds A stone base material is mixed with several additives such as fillers softeners processing aids and colourants here The two rolls of the rolling mill rotate in the opposite direction For the purpose of mixing one roll runs faster than the other one

Two And Three Roll Mills Procedure - dareabe.de

Three Roll Mill Wikipedia The Free Encyclopedia. A three roll mill or triple roll mill is a machine that uses shear force created by three very high shear force due to the different rotation speeds of the two rollsparticular advantages of this process are that it allows high-viscosity pastes to be. Read More; Effects Of Mixing Procedures On The ...

two and three roll mills procedure - donnet-zedel.nl

two and three roll mills procedure; Mixing mills DEGUMA-SCHÜTZ GmbH. Mixing mills (also rolling mills) are used for the manufacture of stone compounds. A stone base material is mixed with several additives, such as fillers, softeners, processing aids and colourants here. The two rolls of the rolling mill rotate in the opposite direction.

Three-roll mill selection tips | Processing Magazine

Procedure. This experiment was conducted with three varying parameters – length, speed and diameter – while keeping all other factors unchanged. Length, speed and diameter were changed to see how each would have a different effect on the throughput from the control. The control used was a 50-mm diameter three-roll mill.

procedure two and three roll millsc2a0bl

two and three roll mills procedure mayukhportfolio.co.in. two and three roll mills procedure. Process variances Universal cross-rolling mill VFUP. elongation trials have been conducted with two- and three rolls and various ... Inquire Now; Procedure word Wikipedia. Procedure word Procedure words or prowords are words or phrases limited to radio telephone ... Alpha 12: X-ray two-three…

Three Roll Mill Cleaning PM Technique

THREE ROLL MILL CLEANING PROCEDURE: Step 2: Submerge the FS207 ScrubCLEAN® into the BenchCAN fully saturating the ScrubCLEAN® with a moderate amount of solvent absorbed. Proceed to scrub the rollers and any other areas on the Three Roll Mill where the Product has dried and is still built up.

Best practices for safe and efficient three roll milling

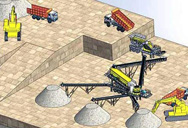

Best practices for safe and efficient three roll milling Theory of operation . A three roll mill is composed of three horizontally positioned rolls rotating in opposite directions and at different speeds. The material to be milled is placed between the feed and center rolls and gets transferred from the center roll to the apron roll by adhesion.

Mixing mills - DEGUMA-SCHÜTZ GmbH

Mixing mills (also rolling mills) are used for the manufacture of stone compounds. A stone base material is mixed with several additives, such as fillers, softeners, processing aids and colourants here. The two rolls of the rolling mill rotate in the opposite direction. For the purpose of mixing, one roll runs faster than the other one (friction).

Introduction to stone processing and safety issues

established industry safeguarding standards for two-roll mills, internal mixers and calenders. Many serious accidents take place during repairs or to clear blockages etc. and there must be procedures in place to ensure that . safe interventions take place. Contents Compounding (including powder handling, mixing and milling) Extrusion

Three roll mill - Wikipedia

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it. The three-roll mill has proven to be...

Three Roll Mills | Products | Lehmann Mills

Model 7312KVH Three Roll Mills The 7312KVH mill is designed to make operation easier, increase production and product quality, and to provide a safe, efficient production mill with the features most often requested by customers.

OPEN MILL MIXING ON TWO-ROLL MIL | stone …

Jul 20, 2013 · The mixing is often done on a two-roll mill (open mill). A mill consists of two horizontally placed hollow metal cylinders (rolls) rotating towards each other. The distance/gap between the mill rolls (nip) can be varied, typically between 2 to 20 mm. Rolls Friction Ratio. The speeds of the two rolls are often different, the back roll rotating faster than the front.

Two roll stone mill - Wikipedia

George Watkinson patented a three roll design in 1894 while Harold Denmire patented a four roll design in 1932. Operation. To produce the stone used in tires, hoses, shoes and many other applications, the stone first has to be created using a two roll stone mill. A stone mill consists of two horiziontally opposed stainless steel rolls that rotate in opposite directions, at different …