tin ore to tin metal process - thesushilounge.be

how tin ore is process - projectmindlab Cleveland ore dressing plant in Australia uses cone separator and hydrocyclone to process coarse and fine particles of tin ore, waste gangue discarded ratio is 40%, tin metal loss in gangue is only 5%. HMS equipment includes hydrocyclone, cone separator, drum separator and DWP cyclone separator, etc ...

Tin Ore Extraction - Mineral Processing & …

The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit.Cassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are necessary to avoid an excessive production of fines. The Mineral Jig is an important feature of this flowsheet to recover the coarse free tin mineral as …

Tin - Wikipedia

Tin is a stone element with the symbol Sn (from Latin: stannum) and atomic number 50. Tin is a silvery metal that characteristically has a faint yellow hue. Tin, like indium, is soft enough to be cut without much force. When a bar of tin is bent, the so-called “tin cry” can be heard as a result of sliding tin crystals reforming; this trait is shared by indium, cadmium, and frozen mercury.

Tin processing | Britannica

9-5-2020 · Tin processing, preparation of the ore for use in various products. Tin (Sn) is a relatively soft and ductile metal with a silvery white colour. It has a density of 7.29 grams per cubic centimetre, a low melting point of 231.88 °C (449.38 °F), and a high boiling point of 2,625 °C (4,757 °F). Tin is

Tin Ore Mining Process - Xinhai

For a certain tin ore dressing plant, Xinhai has taken flotation-gravity process by smashing tiningraw ore to 200mm, and a close-circuit grinding by grinding it to 200mm occupied 60~ 65% . Process of “one roughing- two scavenging-one cleaning” has been applied to the flotation to grind copper and sulfur separately to 0.074mm occupied 95%.

Tin Mining and Processing: Everything you Need …

GK Home > GK Blog > Tin Mining and Processing: Everything you Need to Know Over the course of mining history, great progress has been made in the way materials are extracted from the earth. Compact, heavy-duty equipment has increased efficiency and cost-effectiveness while helping to reduce waste and harmful chemicals.

Tin processing - Mining and concentrating | …

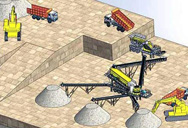

Tin processing - Tin processing - Mining and concentrating: Vein deposits, such as those in Bolivia and the United Kingdom, usually occur in granite formations and are recovered by conventional underground hard-rock mining techniques. In deep mines, primary crushing equipment is usually located underground in order to reduce the ore to a manageable size …

How tin is made - material, used, processing, …

Process The process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore. The tin deposits in Bolivia and England are located deep underground and require the use of tunnels to reach the ore.

Tin mining - Wikipedia

Tin extraction and use can be dated to the beginnings of the Bronze Age around 3000 BCE, when it was observed that copper objects formed of polymetallic ores with different metal contents had different physical properties. The earliest bronze objects had tin or arsenic content of less than 2% and are therefore believed to be the result of unintentional alloying due to trace metal …

Tin Ores | Article about Tin Ores by The Free …

Tin Ores natural mineral formations with a sufficiently high tin (Sn) content to make commercial extraction profitable. Cassiterite, which contains up to 78.8 percent Sn, is the most valuable tin ore. Stannite, with 27.5 percent Sn, also contains good industrial concentrations of Sn but is not very widely used because of the numerous difficulties ...

Tin Ore Mining Process with Magnetic Separator …

Tin Ore Mining Process Abstract: Tin ore has high economic value and its raw materials include lots of other materials such as iron ore. To get the high grade tin ore, it needs to have the separation and milling stages to remove these materials. liming can provide the tin ore magnetic separator, tin ore grinding mill and gravity separator.

How Tin is Recycled - SAMaterials

Tin is produced directly from concentrates, it is called primary tin, tin is obtained from metallurgy of tin containing waste, which is called recycled tin. The comprehensive exploitation and utilization of recycled tin resources include tin associated ore, paragenetic ore, tailings produced during ore dressing, slag and soot produced in smelting process, and utilization of other wastes.

tin coating process - YouTube

24-2-2016 · Tinplate is coated with a layer of tin metal, and it is not easy to rust, also known as tinplate. Such coated steel in China for a long time called "tin", some people believe that tin …

Extraction of tin from its ores - Manchem Limited

20-1-1987 · 13. The process of claim 12 wherein the metal content of the unrefined tin ore is utilized as in situ metallic catalyst. 14. The process of claim 1 wherein prior to heating said unrefined tin ore with a hydrocarbyl halide, said ore is …

Tin sources and trade in ancient times - Wikipedia

Tin is an essential metal in the creation of tin bronzes, and its acquisition was an important part of ancient cultures from the Bronze Age onward. Its use began in the Middle East and the Balkans around 3000 BC. Tin is a relatively rare element in the Earths crust, with about two parts per million (ppm), compared to iron with 50,000 ppm, copper with 70 ppm, lead with 16 ppm, …

Making Bronze - YouTube

11-4-2017 · Melting copper and tin to make a bronze alloy composed of 90% copper and 10% tin. The bronze will be used for future casting projects, …

Smelting - Wikipedia

Smelting is a process of applying heat to ore in order to extract a base metal.It is a form of extractive metallurgy.It is used to extract many metals from their ores, including silver, iron, copper, and other base metals.Smelting uses heat and a stone reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind.

Smelting - Cornish Mining WHS

Smelting is the process of extracting a metal (like tin or copper) from its ore. Most ores are a stone compound of metal with other elements, like or oxygen sulphur. Smelting uses heat and a reducing agent, like coal, to remove these other elements from the metal.