grinding of cement slurry - evviva-vitaal.nl

major component of Portland Cement Concrete Slurry pH neutralization tests were performed by blending compost (from two different commercial sources) with PCC grinding slurry at three slurry:compost ratios and monitoring pH as a function of time The pH of the soil in the non-impacted area on SR-195 was in the range 63-75

Grinding Of Cement Slurry - Collegium …

grinding of cement slurry eautrementbellebe. Pictured at the top, wet concrete grinding produces slurry Pictured in the middle, apply the slurry solidifier over the slurry and sweep the remains into a pile. grinding slurry plant processing biofuels2050eu. What Is The Proper Method For Concrete Slurry .

grinding cement with water - quackband.nl

grinding cement with water . ... 340.3.2 Concrete Pavement Grooving and Grinding Residues Grinding and grooving generate concrete slurry residue from cooling water and ground concrete particles that must ... The Pavilion8 Cement Grinding Application offers process and quality control independent of system configuration.Whether faced with a ...

Cement - Extraction and processing | Britannica

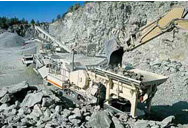

6-6-2020 · Cement - Cement - Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

MillMaster + SmartFill for ball mills; Innovative …

9-3-2018 · "Electronic ear" is not "electronic ear"! It is time to make clear that there are fundamental differences between electronic fill-level measurement systems for ball or tube mills. Whenever I am ...

What Is The Proper Method For Concrete Slurry …

If you have already collected the slurry in drums or pits, both AQUAmaxx and ECO-QUICKgel can help with your slurry disposal. Add AQUAmaxx to reduce the amount of waste and just decant the water. Then add ECO-QUICKgel to solidify the remaining concrete slurry. With both products, it is best to mix it in the concrete slurry to create a faster reaction and speed up processing time.

grinding of cement slurry - NIZZI SARA

Diamond Grinding of Portland Cement Concrete Pavements. grinding extremities in each lane. Verify that the diamond-grinding operation conforms to project requirements. Verify that concrete slurry is adequately vacuumed from the pavement surface and is not allowed to flow into adjacent traffic lanes. Depth Land Area Groove. Figure 1.

how to make project report on grinding unit of …

139 cement plants, 365 mini plants & 40 players, the cement industry in India is ... according to the latest RNCOS report titled, Indian Cement Industry Outlook 2016. ... of cement consumption, that the Southern region is creating maximum demand, ... project at its Jamul plant in Chattisgarh and its grinding unit in Jharkhand.

Cement Manufacturing Process: What is Cement …

Cement manufacturing process & what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

US2141571A - Grinding of cement clinker - Google …

US2141571A US49064A US4906435A US2141571A US 2141571 A US2141571 A US 2141571A US 49064 A US49064 A US 49064A US 4906435 A US4906435 A US 4906435A US 2141571 A US2141571 A US 2141571A Authority US United States Prior art keywords cement grinding mill clinker added Prior art date 1935-11-09 Legal status (The legal status is an assumption and is not a legal conclusion.

Cement Manufacturing Process | Phases | Flow …

Cement Manufacturing Process Phase III: Pre-heating Raw Material After final grinding, the material is ready to face the pre-heating chamber. Pre-heater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln.

Mill (grinding) - Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().

CN101898878B - Cement grinding aid - Google …

The invention discloses a cement grinding aid, comprising calcium formate solution, compound glycerol distilled residue solution, triethanolamine, diols and molasses. While the product reutilizes the industrial wastes, the components of the product synergistically act to optimize the efficacy of the grinding process and the product modifies the cement particles, thus improving the quality and ...

cement grinding processes - Verkeersacademie …

Jan 15, 2020 · Grinding is the next step in the cement manufacturing process, and it can occur in either wet or dry forms. Wet grinding involves combining all of the materials in a mill with water and grinding it into slurry. In contrast, dry grinding processes combine and grind the materials without water, creating a substance known as kiln feed.

Process In Cement Grinding - itisfocaccia.it

Process In Cement Grinding; ... Cement grinding using Grate Discharge principles developed in the ore milling industry applied to the cement industry. ... Then the slurry is led . Grinding plant Fives in Cement Minerals. QNCC (Qatar) Raw meal and cement grinding plants with B-mill; Cementos Moctezuma (Mexico) ...

grinding cement improving - Fotografiemonique

Cement grinding aid characteristics ... the dispersion of the particles and the flow state of the slurry. Diamond grinding of pavement - Wikipedia. For grinding asphalt to remove old pavement, see pavement milling. Applications. There are many surface issues that diamond grinding …