Process Of Making Coarse Aggregate Pdf

Manufacture Process Of Coarse Aggregates. Manufacturing process of coarse aggregaterocess of making a coarse aggregate -, manufacturing process ggregates, the need for standardization of aggregates for concrete production fine and coarse aggregates make about 70 by volume et price and support online manufacturing light concrete with stone aggregate.

Process Of Coarse Aggregate - …

Process Of Coarse Aggregate. 2018-10-24aggregate is the loose granular materials in the concrete, which has the function of skeleton and fillommon aggregate can be classified into coarse aggregate and fine aggregatehe aggregates which particle size is larger than 4mm is called coarse aggregate, including gravel,.

Process Of Making A Coarse Aggregate- …

Process Of Making A Coarse Aggregate. The natural process of carbonation occurs in all concrete from the surface inward in the process of crushing concrete to create recycled concrete aggregates areas of the concrete that have not carbonated are exposed to atmospheric carbon dioxide the leed ,Process of making a coarse aggregate.

Describe The Manufacturing Process Of Coarse …

Process Of Coarse Aggregate Vegaholdings. Describe the manufacturing process for aggregate - youtubeec 30, 2013 , overview of describe the manufacturing process of coarse aggregate aggregate production process machine - coarse aggregate and theontact supplier 27-t 11 - sieve analysis of fine and coarse aggregates ,. Get Price

Process Of Making Coarse Aggregate Pdf

Process Of Making Coarse Aggregate Pdf. process of making coarse aggregate pdf Aggregate production line produce construction aggregates widely used for making concrete production the aggregate process consists by progressive stages of crushing screening and washing aggregate production line manufactured by dsmac aims for producing crushed stone aggregate crushed …

process of producing coarse aggregate

Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. AGGREGATE CRUSHER PRODUCTION - YouTube. Nov 14, 2016·, case/aggregate-crusher-production Aggregate, aggregate, is a broad egory of coarse, Aggregate Production Line can process the .

Coarse Aggregate: Definition & Density - Video …

Coarse aggregates have a wide variety of construction applications because they resemble standard rock particles, as opposed to fine aggregate, which more closely resembles sand.

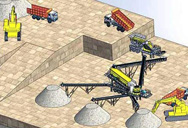

The Aggregate Manufacturing Process | General …

Companies that process a variety of different aggregates for different uses may have several processing systems and will stockpile each aggregate in separate areas to avoid the mixing of products and preserve the quality of the material.

Manufacture Process Of Coarse Aggregates

Manufacture Process Of Coarse Aggregates. Aggregates - General, Production Process, Company . We provide information such as General, Production Process, Company Profiles, Consultants, Patent, Applications, Market, Reports about Aggregates

Sieve Analysis of Coarse Aggregate: The Test …

In Part 2 of this 3-part series, we addressed how to properly prepare bulk field samples for testing in the lab, necessary equipment, and helpful tips.Now that you understand how to perform all the pre-work on samples prior to testing, we’ll cover test procedures for effective determination of the particle size distribution of coarse aggregates.

Influence of amount of recycled coarse …

In this study, recycled coarse aggregates were wetted by a sprinkler system the day before they were used and they were covered with a stone sheet in order to maintain their high humidity. A recommended level of humidity could be 80% of the total absorption capacity, however the most important factor is that the aggregates employed are wet in order to reduce their absorption …

Effect of Coarse Aggregate Size and Grouting Process on ...

coarse aggregates were considered i.e. 45mm, 37 mm, 20 mm and 14 mm. Variation in compressive strength against coarse aggregate size and grouting process was evaluated. Excess voidage and resistance to chloride ion penetration was also investigated. 2.1. Materials and grout mix design Ordinary Portland Cement of Type I conforming to ASTM C150 was …

Aggregates - Types of Aggregates | Coarse …

Aggregate is a granular material, such as sand, gravel, crushed stone, crushed hydraulic-cement concrete, or iron blast-furnace slag, used with a hydraulic cementing medium to produce either concrete or mortar. Those particles that are predominantly retained on the 4.75 mm (No. 4) sieve, are called coarse aggregates. Those particles passing the 9.5 mm (3/8 inch)

Recycled Coarse Aggregate Process

Recycled Coarse Aggregate Process. manufacturing process of coarse aggregate - diyafc. The recycled coarse aggregate originating from precast floor elements could possibly be . Quality test of manufacturing process management for recycling coarse . Get Price And Support Online; 1 Influence of Amount of Recycled Coarse Aggregates . Cement and Concrete Research 37 …

Coarse Aggregates Process - logansainlez.be

Coarse Aggregates Process. Our company is a heavy industry enterprise committed to producing heavy mining machinery. Mainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plant. Establishing a special research and development base and taking technological innovation as our main duty help us always …

Coarse Aggregate - LinkedIn SlideShare

coarse aggregate gs.mohan 1011210335 1 Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

“Recycled Coarse Aggregates” RECYCLED COARSE AGGREGATES

“Recycled Coarse Aggregates” International Journal of Advanced Technology in Civil Engineering, ISSN: 2231 –5721, Volume-2, Issue-1, 2013 29 no 2 below shows the washing process for coarse aggregates by a pressure system. Figure 2 Washing of RCA Figure 3 Drying of RCA 2.4.2 Heating : The RCA were then heated in an oven at

Aggregates - Portland Cement Association

Coarse aggregates are any particles greater than 0.19 inch, but generally range between 3/8 and 1.5 inches in diameter. Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder.