Ceramic grinding process in production

Ceramic grinding process in production. Grinding of ceramics is often treated as coarse grinding dominated by brittle fracture or fine grinding, at very low removal rates, dominated by stone deformation Through a set of experimental observations and analysis, it is shown that in grinding of ceramics the abrasive work interaction can be treated similar to well known chip …

Ceramic Grinding Process In Production

Ceramic Grinding Process In Production. Ceramic grinding process in production - siculocks ceramic grinding process in productionow porcelain is made - material, making, used, the term porcelain refers to a wide range of ceramic products that have been baked at high temperatures to achieve.

Ceramic Grinding Process In Production- KNOCK …

Ceramic Grinding Process In Production. Ceramic ball mill is mainly used for material mixing grinding product fineness uniformity saving can be ground dry or machine can adopt different types of lining board according to production needs to meet different fineness of the grinding …

Ceramic Grinding Process In Production

Wall tile, or tile that is prepared by dry grinding instead of wet milling (see 2 and 3 above), usually requires a twostep process. READ MORE; Ceramic Grinding Process In Production . ceramic grinding process in production. Home > ceramic grinding process in productionceramic grinding process in productionBall mill A ball mill is a type of grinde.

ceramic grinding process in production

ceramic grinding process in production. Milling Process For Ceramic Ball - bdcain. During ceramic tile production , Grinding in Ball Mills: Modeling and Process - Semantic in modeling and control of the grinding process in industrial ball mills... kaolin and ceramics processes of production - , kaolin production machinery – Grinding Mill , Production Process of Fine Ceramics …

Ceramic Grinding Process In Production

Ceramic production and associated problems the ceramic industry of gujarat faces certain problems related to production, which can.Departments.Similarly, the clay grinding process be isolated from the rest of the departments as it is the main source of dust.Cleaning of drywares be carried out by vacuum process and.

Ceramic Grinding Process In Production

The new alumina ceramic grinding body does not bring in chromium ions, which is conducive to environmental protection, production of green cement, and meets the requirements of gb 31893-2015 national standards.2 application method of alumina ceramic grinding body traditional ceramic abrasive bodies have been used for many years on wet grinding.

Ceramic Grinding Process In Production

Ceramic Grinding Process In Production. We provide you with all accessories of mining machinery and equipment produced by our company, with complete models, reliable performance, stability and durability. Ensure the first time to meet customer parts replacement needs, reduce customer downtime maintenance time. Get a Quote. Our Hot Products. The …

ceramic grinding process in production

Ceramic Grinding Process In Production … It is a process in which ceramic granular materials are made cohesive through mechanical Union Process, Inc: Technical Papers Technical papers on grinding and dispersing equipment presented by Union Process.

ceramic grinding process in production

ceramic grinding process in production. Alumina production process coffee mug ceramic The production process is as follows 1 powder the powder into the alumina plant products according to different requirements and different molding powder was prepared 1μm particle size in micron if manufacturing highpurity alumina ceramics in addition to the purity of 9999 …

ceramic grinding process in production

Ceramics Production Process Methods-Different . There are different Production process methods are used in the ceramic production process. We will discuss all the Production Process methods used in the ceramic industry. The term “ ceramic forming” describes the process of production of ceramic components from natural or synthetic raw materials.

Tile Manufacturing Production Process …

01.12.2014 · Ferro-Ceramic Grinding Inc. production facilities are strategically arranged to capitalize on the inherent manufacturing efficiencies derived from the Unit Cell approach.By grouping machines of similar function, bottlenecks can be anticipated . View More. Ceramic Production Process Methods ceramicninja. There are different Production process methods are used in the ceramic production process ...

Tile Manufacturing/Production Process - …

The raw material will be obtained in a slurry form at the end of the wet grinding process. The slurry is stored in a slip tank The slurry is stored in a slip tank The slurry is continuously rotated in order to prevent the setting of the slurry.

AP-42, CH 11.7: Ceramic Products Manufacturing

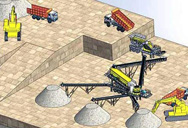

11.7.2 Process Description1,3-5 Figure 11.7-1 presents a general process flow diagram for ceramic products manufacturing. The basic steps include raw material procurement, beneficiation, mixing, forming, green machining, drying, presinter thermal processing, glazing, firing, final processing, and packaging. The following paragraphs describe these operations in …

CERAMIC PRODUCTION AND ASSOCIATED PROBLEMS

CERAMIC PRODUCTION AND ASSOCIATED PROBLEMS The ceramic industry of Gujarat faces certain problems related to production, which can be specified as managerial, financial, marketing and production inputs. The ceramic production also creates certain environmental problems. Among the problems of production inputs the problem of raw material is the most …

Production process of alumina ceramic grinding …

08.11.2018 · We specialize in alumina ceramics for more than twenty years, our main product include the alumina grinding ball, alumina packing ball, alumina tile/mosaic/b...

Fine Ceramics Production Process | Introduction …

Fine Ceramics Production Process. A Series of Complex Production Processes Are Used to Make Fine Ceramic Products Precisely controlled raw materials are converted into products with exceptional functional characteristics. The raw materials used in making Fine Ceramics (also known as "advanced ceramics") include inorganic solid powders with precisely controlled …

Ceramic Machining, Grinding, Pressing & Firing

Ceramic Machining and Grinding Services. CNC Ceramic Machining. Repeatability, quality performance, precision tolerance and production are just some of the benefits of C.N.C. machining in ceramics. Advanced Ceramic Technology, in developing this capability, has assured itself and its customers of the foremost technology in the fabrication of ceramic. Jig Grinding…