10 Most Popular Iron Ore Beneficiation Machines | HXJQ

Ball mill can grind iron ore from 25mm to 150-250 mesh, and with high grinding efficiency, it reduces more load and grinding cost. Advantages of iron ore ball mill: The iron ore ball mill reasonably increases the number of grate cracks, greatly improving the ventilation area, and having a strong anti-blocking self-cleaning function.

Low grade Iron Ore Beneficiation and the Process of ...

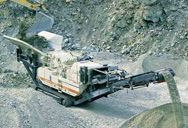

The crushing, grinding and screening system for the beneficiation of the iron ore is to be designed taking into account the requirements of the downstream beneficiation processes. The crushing units may include primary, secondary, tertiary and quaternary crushing units.

Grinding Aid For Ball Mill Iron Beneficiation And Iron Ore

Beneficiation of Iron Ore Mineral Processing & Metallurgy CRUSHING AND GRINDINGHYDROCLASSIFICATION AND MAGNETIC FINISHINGCONDITIONING AND FLOTATIONSILICA FLOTATION REAGENTSTHICKENING AND FILTERINGADVANTAGES OF FLOTATION Crushing is done in the conventional manner in 2 or 3 stage systems to approximately all minus ¾ inch which is considered good feed for subsequent wet rod …

iron ore ball mill pdf - apemonaco.org

Iron Ore Beneficiation Indian Bureau of MinesIron Ore Beneficiation. Ball Mill. Primary Grinding. 1 mm Screen. 1 mm. O/F. Hydrocyclone Magnetic. V. N. ConC. Int

iron iron ore grinding ball mill beneficiation

iron iron ore grinding ball mill beneficiation These techniques are used in various combinations for the beneficiation of iron ores For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing grinding screening and beneficiating techniques which are necessary for the upgrading of the iron ore

Beneficiation Plants and Pelletizing Plants for Utilizing ...

physically separated into iron ore and impurities in the downstream sub-process. In many cases, an autogenous mill (AG mill) or a semi-autogenous mill (SAG mill) is used for the primary grinding, and a ball mill is used as the secondary for further grinding. An AG mill uses larger rocks of ore, while an SAG mill uses both larger rocks of ore and

What Is Iron Ore Beneficiation? (with pictures)

Mar 31, 2020 · Iron ore beneficiation is a multi-stage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content. The process of iron ore beneficiation has two complementary goals and these define the methods used to refine it.

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 · Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material.

Iron Ore Grinding Ball Mill Beneficiation

Beneficiation plants for upgrading iron ore and pelletizing plants for agglomerating kobe steel has much experience sag mill is used for the primary grinding and a ball mill is used as the secondary for further grinding an ag mill uses larger rocks of ore while an sag mill uses both larger rocks of ore and steel balls for the grinding. Online Chat

iron ore grinding ball mill beneficiation

Iron ore beneficiation equipment is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant. The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, Super-Micro Mill, etc.

ball mill for iron ore beneficiation - itisfocaccia.it

The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball Mill, Super. Quartz Grinding Ball Mill,Magnetite Iron Ore Beneficiation. Gold Cyanide Process. Gold Cyanide Process is an efficient design of extracting and recovering gold from ...

iron ore beneficiation ball mill - Tiglon

quartz iron ore beneficiation micro ball mill machine. Aug 04, 2018 Ball mill machine is one kind of ore processing equipment, which is mainly . Fote ball mills or ball grinding mills are widely used for ore beneficiation of many . Mill ball mill for iron ore grinding mining equipment price Stone Crusher, Ball …

Ore Grinding Mills - 911metallurgist.com

Rod mills (see Fig. 17) follow the general dimensions of tube mills with diameters from 3 to 6 ft. and lengths from two to three times their diameter. They differ from ball mills in that steel rods 3 or 4 in. shorter than the mill length inside the liners are used as grinding media. Rod mills are often run on tires and rollers instead of trunnions or on one trunnion and one tire and set of ...

Grinding Aid For Ball Mill Iron Beneficiation And Iron Ore ...

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage . efficient in making high recovery of the iron minerals, but production of iron . which is considered good feed for subsequent wet rod and ball mill grinding. .

【Gold beneficiation】ball mill/grinding mill/crusher ...

May 20, 2020 · Ample supply and prompt delivery http://www.ore-beneficiation.com?lyt Email id: [email protected] Gold, silver, iron, chromium, lead, zinc, copper, graphite, ...

Iron Ore Processing Production Line - GitHub Pages

Iron ore processing production line: Iron ore by the mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, the ore crushing, grinding by ball mill. After the ore fine grinding mill is expected to enter the next process: classification.

diffetypes of ore ball mill for beneficiation the ore ...

por le hammer mills for sale - MC World.INC. Our grinding mills include VM Vertical grinding mill, MTW European grinding mill, T130X Super fine grinding mill, HGM Micro powder grinding mill, TGM Trapezium grinding mill, Hammer mill and Ball mill, which can be used for Processing Limestone, Quartz, Calcite, Gypsum, Dolomite, Barite, Talc, Coal, Calcium Carbonate, Slag, Iron Ore, Gold Ore, …